ARTICLES & HOW-TOS |

Power Tools for Ship Modeling

Mike Lonnecker

When starting to build that first ship model, probably a kit, the neophyte model builder starts with hand tools. As one's skills progress and projects become larger and more complicated, power tools make some aspects of construction easier, faster and/or more accurate. Power tools are not the nirvana of ship modeling. Like any hand tool, each power tool requires its own set of skills and practice to safely and accurately produce parts. Unless one is a trained machinist, learning to make setups and manufacture the intended part will require a great deal of study and trial and error. Safety and using the proper tool for the job are paramount.

Below I will discuss several of the most useful power tools for a modeler's shop. The discussions will point out how each tool might be used to help in the production of a ship model. The list is by no means a complete one. As with hand tools, I highly recommend that you do not rush out and buy a shop full of power tools. Work on your project until a need is visualized. Do your research and learn as much as you can about the operation and capability of the tool and what is available; then make an informed purchase.

The list below will make mention and/or show pictures of some specific brands and models of power tools. This is by no means an endorsement of that specific tool but is my way of illustrating what might be available and ways that it might be used. Do your own research and determine what best fits your need and budget. Discussions of the tools is in no particular order or preference for purchase.

ROTARY TOOLS

The Dremel tool is the standard of this category. This is a hand held motor that spins cutting tools to perform all kinds of cutting, carving, grinding, routing, sawing, sanding and drilling operations using interchangeable collets and chucks. They are available in plug-in and cordless models. The accessories for rotary tools are endless. Cutting, grinding, routing/shaping, sanding disks, sanding drums and saw blades are available many sizes and shapes. Additional accessories include many fixtures that use the rotary tool as a power source. Routing tables and bases, drill presses, right angle drives and flex cable drives are some of the available accessories.

Another type of rotary tool has a remote motor with flex shaft driven hand piece. One popular brand is made by Foredom. Accessories are similar to or interchangeable with the Dremel style tool. One might also consider some of the smaller, less powerful, hand held tools intended for light carving duty. These turn at RPM’s equal to Dremel style tools but don’t have the power or torque. They are however much lighter and smaller in the hand and can be easier to control. An example are those made by WeCheer. Safe use is fairly intuitive. Always wear safety glasses when using and carefully control the tool to prevent injury.

Dremel Rotary Tool

WeCheer Rotary Tools

Foredom Flex Shaft Tool

DISC SANDERS

A disc sander is a machine with a vertical disc with a sheet of adhesive sandpaper spun by a motor. The disc is mounted next to a table to support the part being sanded. They are available in disc sizes from the 3-6" table top varieties to 12" or larger industrial varieties. The disc sander is one of the most used power tools in my shop. Producing parts to make exact fits for joinery or to each other is much better achieved by sanding than by cutting with a chisel or saw. The sanded edges and corners are left sharp and with proper set-up, multiple parts of the exact size, length, angle and shape can be easily achieved. Outside curves, such as those of a hull frame can also be sanded very accurately. It seems that almost every part I make ends up at the disc sander. It can be used to sand wood, softer metals such as brass or aluminum and plastic.

The most important feature of the disc sander is the disc itself. The disc must be true and capable of maintaining its shape under use. A billet and machined disc will outperform one that is stamped from sheet metal. The disc table must also be substantial to hold its shape over time and operation. The table should have a tilt feature that can be securely locked at precise angles and should also include an adjustable miter gauge. These features will allow shaping of vertical and horizontal angles simultaneously. Adhesive sandpaper disks are available in grits from 80 to 600. I find grits of 180-200 to be the most useful. Do not forget your safety glasses and keep your fingers away from the spinning disk.

Byrnes Model Machines Disk Sander

TABLE SAW

Table saws, like disc sanders, comes in various sizes with blade diameters of table top models of 3" to 12" or larger for commercial cabinet saws. The table top saw with a 3-4"bade is the most suitable for our modeling work. The saw can be used to cut material to width, length or angle and to cut grooves and dadoes. Wood or plastic such as Plexiglas can be cut with a standard blade. By changing the saw blade to a cutoff or abrasive wheel or slitting blade, soft metals and fiberglass can be cut. Most of the table top models produce very accurate cuts and are a must if you want to produce your own strip wood. There are two types of table saws available, tilting arbor and non- tilting. The tilting arbor allows the blade to be tilted up to 45o for angle cuts. Both arbor types allow blade elevation to control the depth of cut. An example of the tilting arbor type is sold by Micro Mark. Byrnes Model Machines makes an excellent non-tilting arbor saw. Arbor diameters vary among the saws. Blades are available in many kerfs (blade thickness) and tooth types. Kerfs can be less than 0.016" for slitting blades, up to 0.060" for some carbide toothed blades.

Saw accessories are manufacturer specific and include sliding tables, tilting tables (to compensate for a fixed arbor), miter gauges, fence extensions, table extensions, and micrometer control of the fence location. Safe operation is critical and is the same if whether you are operating a full size cabinet saw or a table top model. Even the small table top models can cause severe injuries. Guide books from your local library or woodworking store are good sources for safe operation and tricks for producing parts. Adult education classes at your local high school or college are also a good source. Please study and learn safe operation of your saw before trying to produce any parts.

MicroMark Saw

Preac Saw

Byrne’s Model Machines Table Saw

DRILL PRESS

The drill press has a vertical spindle driven by a motor. The rpm of the spindle is controlled either by a variable speed motor or by moving a belt between pulleys. The spindle holds the drill for drilling in material mounted or clamped to the table below. The spindle can be lowered by use of a handle to drill at a controlled rate and depth. The spindle can hold drills of various sizes in a chuck. Chucks come in various sizes depending on the size of the drill press and the size of hole desired. The depth of the throat controls the size of material that can machined. The primary function of the drill press is to drill holes at right angles to the table. Holes at an angle can be achieved by tilting the table. For safety and accuracy, material should always be held in a drill vice clamped to the table or clamped directly to the table. Drill presses can be purchased from small desktop models up to large floor mounted models. There is even a drill press accessory for the Dremel. This product is not as accurate as a dedicated drill press but might suffice when the budget and space are limited. In most models the table can be moved vertically along a column to accommodate materials of various thicknesses. A sanding drum can also be chucked up to do light sanding.

Dremel Accessory

Proxxon Drillpress

Jet Tabletop Drill Press

LATHE

A lathe produces parts by spinning them about a longitudinal centerline. The outside shape that is produced can be cylindrical, tapered, grooved, beaded, almost any curved shape. Inside shapes can be drilled or bored. Threads can be turned both internally and externally. Lathes are specified by the swing (maximum diameter that can be turned over the bed of the lathe) and the distance between centers (maximum length of a part). Lathes come in two basic types: metal turning and wood turning. A metal turning lathe can turn almost any material including metals, wood and plastics. A wood lathe is designed for softer materials like wood only.

Cutting tools for a metal lathe are usually high speed steel or carbide and are held in a vise attached to the machine. Cutting tools for the wood lathe are usually a type of chisel that is hand held against a tool post and the material being cut. The wood lathe requires a good degree of skill and practice to operate safely. Professional lessons might be in order here, but study from books at a minimum. The wood lathe is good for turning masts, spars, spindles, buckets, barrels, deadeyes, etc. If equipped with an indexing plate the staves of the barrel can be accurately marked off. Wood lathes come in variable speed models or the speed can be controlled by changing a belt between pulleys.

Jet Wood Lathe

The metal lathe is the more useful of the two to the ship modeler because of its ability to cut both hard (metal) and soft (wood) materials. Sizes range from table top versions of 7x14 and smaller up to huge industrial models. Anything that can be made on a wood lathe can be made on a metal lathe. Commonly made items are cannon barrels and ship's bells. Models by Sherline and Tiag are both USA produced and are of good quality. MicroMark offers one of slightly larger size. More sophisticated machines can also cut threads for making screws. Sherline makes an almost endless line of accessories many of which can be used lathes manufactured by other companies.

When purchasing a lathe budget about 1⁄2 your investment for the basic tool and 1⁄2 for cutting tools and accessories. Making set ups and producing accurate parts requires a lot of skill and forethought. A book written by Joe Martin of Sherline titled “Tabletop Machining” is an excellent guide to the why’s and how’s and safe use of the lathe and mill to be discussed next. Sherline’s web site also offers basic set up and operating instructions and videos. Speeds (how fast the material is rotating) and feeds (how fast the cutter is pushed into the material controlling depth of cut) are the most important aspects of using the lathe successfully. Speeds and feeds can be found in charts in machinists handbooks. When evaluating which lathe to purchase, remember that large lathes can produce small parts but small lathes can only produce a product as long as the distance between centers.

Evaluation of what accessories are needed and available to fit the lathe of your choice requires careful study and understanding of their function. These include chucks and collets mounting to the headstock and whether they are screw on or taper mounted or can be both. The tailstock should have a Morris taper for mounting dead or live centers. Some lathes (Sherline for example) have a hollow headstock that allow material longer than the distance between centers to be fed into the lathe. Another question to ask is, does it include a compound cross slide or just a cross slide. The compound type allows the movement of the cutting tool at an angle to the bed of the lathe. Power feeds for the cross slide are helpful for smooth even cuts. Tool holders are another area to look at. The basic type just holds the tool with hold down screws that must be loosened to change or adjust the cutting tools. Turret type can hold multiple cutting tools that are rotated into position for use. Quick change holders are also available for most lathes. Hand wheels that control the movement of the cross slide and thus the cutting tool, are available in metric units or English units. The rotational speed of the headstock can be set by variable speed (preferred) or by moving a belt between pulleys. The speed that the cross slide moves is controlled by the speed of the headstock rotation. By changing the internal gearing of the lathe, the speed of the screw that drives the cross slide can be varied. This feature allows one to very precisely control the feed of the cut. Also, by changing gears, the ratio of headstock to cross slide ratio is changed letting the machine cut different pitch screw threads. Change gears can be metal or plastic.

Sherline Lathe

Variable Speed Lathe from Micromark with Change Gears

MILL

The mill is similar to the drill press in that it is comprised of a vertical spindle with a table underneath. The difference is in the accuracy and versatility. The spindle is raised and lowered very precisely with a calibrated hand wheel and the table can be moved very precisely side to side and forward and back, also with hand wheels. This gives very precise control of the cutter and material in 3 dimensions or the X, Y and Z planes. Hand wheels screws that move the spindle and table are available in metric or English units. The mill, because of its versatility, is said to be the only machine in the shop that can reproduce itself. Sizes from tabletop to huge are available.

There are lots of accessories available. Material hold down sets, collet sets, vises, tilting tables, rotary tables, chucks... the list of accessories is almost endless. Sherline offers a vast list of accessories that are usable on most tabletop mills. Cutters for tabletop sized machines come in sizes from 0.005" diameter up to about 3/8" diameter, end mill or ball end types, center cut or not and 2 or 4 flute all depending on material and cut to be made. As with the lathe, your budget should be split about 50/50 between the machine and a selection of accessories. Set ups and use of the machine require a lot of skill and basic knowledge. Again, Joe Martin’s book on tabletop machining is highly recommended. The mill is capable of making straight cuts, cuts on a radius, through cuts, bottom cuts, groves, etc. It can even be set up to perform like a lathe. And just like with operating the lathe, speeds and feeds are an important part of operating the mill.

Tiag Mill

Sherline mill

SCROLL SAW

The scroll saw uses small thin blades moving up and down to make very fine cuts in wood, plastics and soft metals. The scroll saw is very useful for cutting parts from sheet stock and can cut very sharp radii. They can easily be used to cut out interior holes such as windows. Variable speed models are available and are probably the best choice. Because of the motion of the arms moving up and down rapidly some saws tend to vibrate. Higher quality saws run smoothly and are easy to use, while less desirable models can jump all over the table or stand. Other features to look for are maximum thickness of material that can be cut, depth of the throat and maximum tilting table angle. Some models have bellows that are used to continuously blow dust from the area being sawn.

Blades are usually pinless and are held in place by clamps in each arm. Ease of changing and tensioning the blade should be considered. Learning to choose the proper blade, blade tensioning, blade speed feed rate are important things to learn when using the scroll saw. The basic theory of operation can be learned from books but practice is essential in learning its use.

Dewalt Variable Speed Scroll Saw

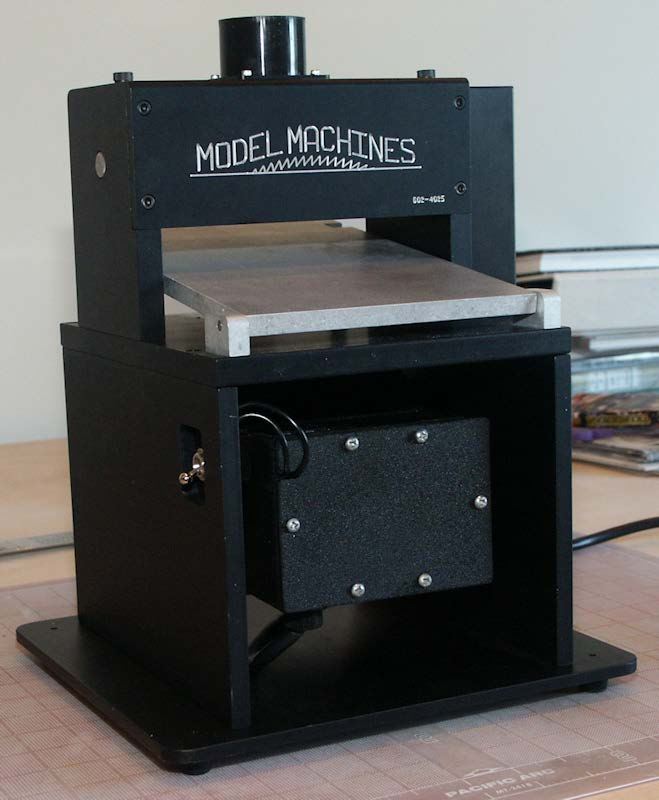

THICKNESS SANDER

If you are going to scratch build and cut your own wood, a thickness sander is a necessity. The thickness sander consists of a table with a sanding drum above it. The gap between the table and drum can be varied by moving the table or drum up or down depending on the model. This precise control gives very accurate thickness and repeatability. In smaller machines, the wood is pushed through the gap by sliding it on the table. Larger machines may have a self-feeding mechanism. The sandpaper on the drum is usually held in place by some kind of a clamp on the drum. The Byrnes Model Machines thickness sander has a dual clamp that allows one grit of paper on the right side and another on the left.

Byrnes Thickness Sander

OSCILLATING SPINDLE SANDER

The oscillating spindle sander consists of a fixed table with a vertical drum that is rotated and oscillated up and down simultaneously. This up and down motion spreads the wear on the sanding drum. The spindle sander is great for sanding inside curves to shape. Most sanders come with a set of replaceable drums of varying diameter. Using a diameter just smaller than the curve to be sanded makes it easy to control the finished arc to be sanded. A tilt table is an option with some sanders.

Delta Spindle Sander

Grizzly 1 1⁄2 Hp Dust Collector

DUST COLLECTOR

If you acquire a shop full of power tools, dust control will become a priority. Most of the sanding and sawing tools discussed here have some kind of dust collection port. If your tools are set up only when they are being used, then a simple dust collector such as a small Shop Vac, connected to the tool temporarily may be the way to go. If your tools remain set up for use, then a permanent system connected to each tool with directional control valves may be preferable. If using a large permanent system, ground all the piping to prevent static electricity build up within the system. Static electricity in a dust environment can be a huge fire hazard.